Diffrent challenges that you may face and there fixes

Rest assured, we have considered most of the potential issues you may encounter and other customers have dealt with. While installing The Solid Mount®, you may face a minor challenge that requires some additional effort. Some specific procedures can be a bit tricky, especially if you are not familiar with power tools. In such cases, it is advisable to seek assistance from a neighbor or a handyman to complete the process safely. However, we have provided a comprehensive set of instructions to guide you through each step. Just take your time and follow the instructions. Remember we are here to help you, please do not hesitate to reach out to us for assistance and guidance.

Table of Contents

Can a shower bench be installed using The Solid Mount®?

The Solid Mount® is specifically engineered and designed for a single purpose: mounting grab bars into fiberglass surrounds. It is not intended for any other use, and using it for alternative purposes may compromise safety. For instance, attempting to mount a shower chair or bench with The Solid Mount® is not recommended. The design and testing processes for grab bars take into consideration factors such as sheer strength and pull-out resistance. Introducing a shower chair or bench alters these conditions. To ensure safety, we advise installing grab bars using The Solid Mount® and separately acquiring a mobile shower bench or chair to be placed within the shower or tub.

The Solid Mount® is specifically engineered and designed for a single purpose: mounting grab bars into fiberglass surrounds. It is not intended for any other use, and using it for alternative purposes may compromise safety. For instance, attempting to mount a shower chair or bench with The Solid Mount® is not recommended. The design and testing processes for grab bars take into consideration factors such as sheer strength and pull-out resistance. Introducing a shower chair or bench alters these conditions. To ensure safety, we advise installing grab bars using The Solid Mount® and separately acquiring a mobile shower bench or chair to be placed within the shower or tub. Grab bar Flange Does not cover

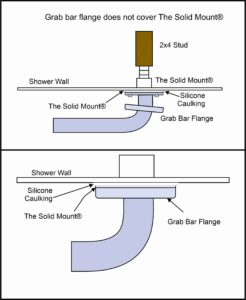

The Solid Mount®

The Solid Mount® is not designed to be covered by the grab bar flange for good reason, flanges on the grab bar are not designed to cover anything more than the flange of the grab bar and the screws.

The Solid Mount® is not designed to be covered by the grab bar flange for good reason, flanges on the grab bar are not designed to cover anything more than the flange of the grab bar and the screws.

This is from one of the largest garb bar manufacturers’ response to a customer from their website, “We take consumer comments very seriously and we are delighted to have the opportunity to assist you. The grab bar flanges are designed to cover the included mounting bracket only and are not designed to cover 3rd party mounting kits.” (Double click on the image to enlarge it.)

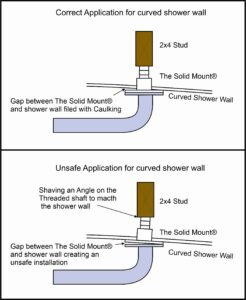

Curved Shower Wall

Curved shower walls are not an obstacle for installing The Solid Mount® in fiberglass showers. Despite some floating ideas like shaving an angle on the threaded shaft to angle the bar, the correct process is actually very simple. By following the instructions, you can easily install the bracket, even if one side has a larger gap than the other. Simply fill in the gap with caulking. While it may not be the most aesthetically pleasing solution, it is a practical one that saves you time and money. There’s no need to tear out the back wall and add blocking. Don’t waste your energy on a complete shower replacement. With The Solid Mount®, you can confidently install grab bars in your curved shower. (Double click on the image to enlarge it.)

Curved shower walls are not an obstacle for installing The Solid Mount® in fiberglass showers. Despite some floating ideas like shaving an angle on the threaded shaft to angle the bar, the correct process is actually very simple. By following the instructions, you can easily install the bracket, even if one side has a larger gap than the other. Simply fill in the gap with caulking. While it may not be the most aesthetically pleasing solution, it is a practical one that saves you time and money. There’s no need to tear out the back wall and add blocking. Don’t waste your energy on a complete shower replacement. With The Solid Mount®, you can confidently install grab bars in your curved shower. (Double click on the image to enlarge it.)

Rear shower wall angled from top to bottom

Navigating an angled shower wall might seem daunting when it comes to measuring for The Solid Mount®. However, rest assured, our provided image offers a comprehensive guide to ensure precision. All you require are a tape measure and a 4-foot long level.

Here’s the basics of how to proceed:

Determine the desired location for the grab bar installation.

Position the bottom of the level against where the grab bar flanges bottom edge.

Keep the level plumb and measure the gap from the level to the drywall.

While these steps may initially sound simple or perplexing, refer to the image for a clear explanation of the process.

(Double click on the image to enlarge it.)

Drywall behind the Fiberglass Shower

Depending on your location, you may discover drywall behind the fiberglass shower. While this isn’t a significant problem, it does require a few additional straightforward steps. Click on the image to view the necessary procedures. Utilizing the 2″ hole saw to drill through the drywall and extract a 2″ section in front of the stud. Following the removal of the drywall, proceed with the installation of The Solid Mount® according to the provided instructions. (Double click on the image to enlarge it.)

Depending on your location, you may discover drywall behind the fiberglass shower. While this isn’t a significant problem, it does require a few additional straightforward steps. Click on the image to view the necessary procedures. Utilizing the 2″ hole saw to drill through the drywall and extract a 2″ section in front of the stud. Following the removal of the drywall, proceed with the installation of The Solid Mount® according to the provided instructions. (Double click on the image to enlarge it.)

Stud less than 7/8" to Fiberglass wall

This situation may seem like a disaster – drilling a 2″ hole in your fiberglass shower might appear to prevent the use of this incredible product. However, fear not. The Solid Mount® is highly versatile, and we have a solution for you; it just requires a bit more time and an additional tool, a 1.5″ spade bit. While this step can be a bit precarious, we recommend using a brand new, sharp spade bit and taking your time. We’ve provided detailed steps along with accompanying images to guide you through the process safely. (Double click on the image to enlarge it.)

This situation may seem like a disaster – drilling a 2″ hole in your fiberglass shower might appear to prevent the use of this incredible product. However, fear not. The Solid Mount® is highly versatile, and we have a solution for you; it just requires a bit more time and an additional tool, a 1.5″ spade bit. While this step can be a bit precarious, we recommend using a brand new, sharp spade bit and taking your time. We’ve provided detailed steps along with accompanying images to guide you through the process safely. (Double click on the image to enlarge it.)

Stud from 2 1/8" to 3" from Fiberglass wall

While not a significant issue, it is important to address it properly to maintain the structural integrity of The Solid Mount®.

While not a significant issue, it is important to address it properly to maintain the structural integrity of The Solid Mount®.

If the gap measures between 2 1/8” to 2 1/4” (See image A), a straightforward solution is recommended. Utilizing the spacer in its current state would result in approximately 2 1/4″ penetration of the lag bolt. We suggest a minimum penetration of 2”, thus for a gap of 2 1/8” to 2 1/4”, acquiring about 4 – 5/16” x 1 1/4” fender washers depending on the brand to fill the gap. Make sure you still have 2″ of lag bolt for penetration.

For larger gaps ranging from 2 5/16” to 2 1/2″ (See image B), the same washer solution applies, along with the replacement of the lag bolt with a 5/16” x 4 1/2” to ensure a minimum 2” penetration.

For spaces exceeding 2 1/2″ up to 3” (See image C), a more thorough approach is warranted. Begin by obtaining a 3/8” drill bit and a 15/64″ drill bit for the pilot hole, and a supply of 3/8” x 1 1/4” fender washers to fill the gap. It’s vital to maintain uniformity in washer size. Additionally, enlarge the 5/16” hole in the spacer to 3/8” to accommodate the larger lag bolt. You can achieve this by using a 3/8″ drill bit, ensuring a snug fit for the 3/8” lag bolt. Lastly, acquire a new 3/8” x 5 1/2″ lag bolt, ensuring it penetrates at least 2 1/2″ into the stud for optimal stability. Also use the 15/64″ drill bit for the pilot hole for the 3/8″ lag boltWe need to change the 5/16″ lag bolt to a 3/8″ lag bolt with 2 1/2″ of penetration due to load changes. (Double click on the image to inlarge it.)

**Notes**

*Only use the fender washers to fill the extra space*

*ANY GAP OVER 3″ WE STRONGLY ADVISE AGAINST IT.*

*DO NOT USE THE SOLID MOUNT® FOR SHOWER CHAIRS*

Still have Questions?

Simple Q&A form